- January 4, 2019

- Posted by: Molding

- Category: Industry News

- Familiarity with assembly procedure

The assembly procedure of injection mold is not only the process document of the assembly process and operation method of the mold, but also the technical document guiding the assembly work of the mold. It is also the basis for the assembly production plan and technical preparation. Therefore, before assembling, workers must read the assembly process regulations carefully, understand and master the whole process of assembling the mold.

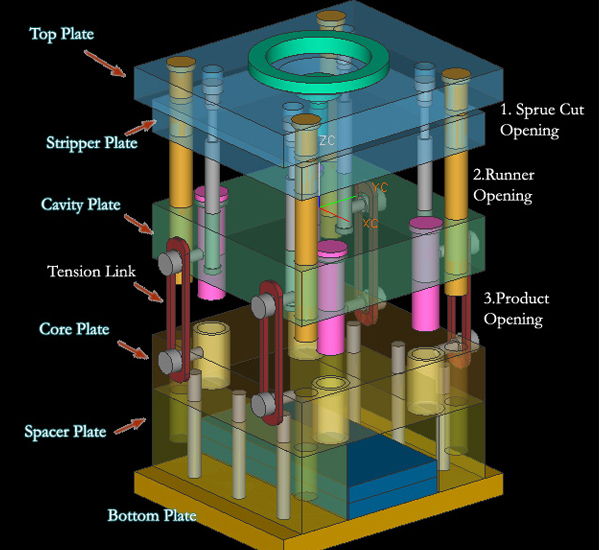

- A thorough understanding of assembly drawings

Assembly drawing is the main basis for mold assembly. Generally speaking, the structure of the die largely determines the assembly sequence and method of the mold. Deep analysis of assembly drawings, part drawings and part drawings can help us to understand the structural characteristics and working performance of the mold, understand the role of the parts in the mold and their interrelationship, cooperation requirements and connection methods, so as to determine a reasonable assembly benchmark, and then formulate assembly methods and assembly sequence in combination with process regulations.

- Checking Parts

According to the detailed list of parts on the assembly drawing, check whether the number of parts is enough, then clean the parts carefully, check the main parts carefully, such as the shape and size tolerance of the cavity, find out the clearance of the fitting surface of each part, the processing allowance, whether there are deformation and crack defects, etc.

- Mould Acceptance Technology

Mastering the technical conditions of mould acceptance is not only the basis of mould quality standard and acceptance, but also the technological basis of assembling. This acceptance technical condition mainly refers to the technical requirements of the technical agreement signed with customers and product drawings and the quality standards promulgated by the state. Therefore, before assembling, workers must fully understand these technical conditions, so that they can pay full attention to the assembling process in order to assemble qualified molds.

- Developing Assembly Sites

When assembling moulds, it is necessary to have a good assembly site, which must be clean and tidy without any debris. At the same time, it is necessary to prepare the necessary workmanship, clamps, measuring tools and other necessary assembly equipment for assembling, wipe them clean and open up a civilized production site.

- Preparing standard parts and related materials

Each set of mold has many standard parts, such as bolts, pins, nuts, springs, etc. Although they are not many in number, they have many specifications. In order to assemble smoothly, at the beginning of assembly, these standard parts must be found one by one in order to be easy to find when assembling. In addition, the auxiliary materials needed in assembly, such as rubber, adhesives, should also be prepared as needed.

JasonMould Industrial Company Limited, established in 2010, is a leading China mold factory. JasonMould specializes in plastic mould production for household appliances, medical equipments, electronic equipments, safety equipments as well as monitoring system.

The company has over 15000 square metres factory. With plastic injection tooling divisions possessing different machinery and expertise, JasonMould offers tools from small and precise mobile phone parts to as big as automotive parts. Our tools are mainly exported to U.S.A., Europe, Japan and UK. JasonMould’s diversification strategy and full service has won compliment from customers all over the world.

Our mission is to provide our customers high quality moulding products and services. We aim to exceed our customers’ expectations of pricing, quality and on-time delivery. To achieve our mission, JasonMould:

- Commits to continually improve employee skills and efficiency,

- Provides our employees a clean and safe working environment,

- Upgrades machine technology and support equipment through a strict maintenance program, and

- Maintains customers’ tooling to its highest peak of performance

For more about China injection molding cost,please visit https://www.jasonmolding.com/

Inquiry Contact:

Contact person: James Yuan

Company name: JasonMould Industrial Company Limited

Address: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Telephone: 86-752-6682869

Email: [email protected]

Website: https://www.jasonmolding.com